Home >> Product >> Stainless Steel Grating

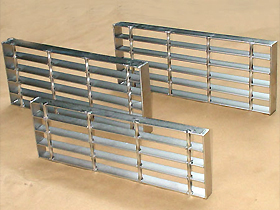

Stainless Steel Grating

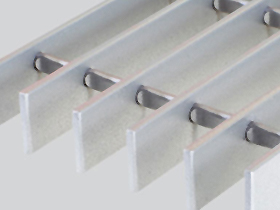

Stainless steel grating has been the standard industrial footwalk product for severe corrosive environments and has been a popular grating choice for many years. Our company manufactures stainless swaged bar grating from type 304 and 316 stainless steel bar. The swaging process allows the assembly of bar grating panels by mechanically locking the cross bars at right angles to the bearing bars at a maximum of 4" on center. This process provides the clean crisp lines of a recessed cross bar and eliminates the discoloration inherent with welded bar grating.

Unless specified, stainless steel grating will have a mill finish. The heat from the electroforge process produces a discoloration to the surface of the welded area. Electro-polishing is a means to remove the discoloration and is available upon request.

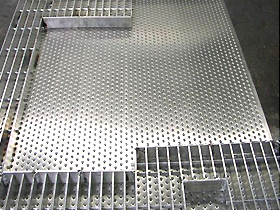

Stainless Steel Grating Application

Power plants, chemical plants, oil refineries, steel mills, machinery factories, shipyards, paper mills, cement plants, pharmaceutical, food processing plants and bridge engineering, municipal engineering projects.

Stainless Steel Grating Specification

Model Description

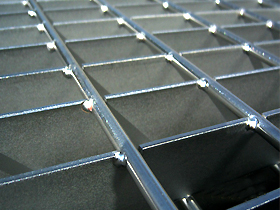

1) Bearing Bar Specification: 1", 1-1/4" ,1-1/2" x 1/8", 3/16", 1/4" (Height X Thickness)

2) Bearing Bar Spacing:1/2", 3/4",1",1-1/4",1-1/2"etc, also be according to client' s requirement and 3/8",2" are recommended

3) Bearing Bar Surface:Smooth - Standard surface ; Serrated - Serrations are cut into the grating's bearing bars surface

4) Cross Bar Spacing:1-1/2", 2", 2-1/2", 4" etc, also be according to client's requirement and 2", 4" are recommended

Stainless Steel Grating Surface Treatment

polishing

Stainless Steel Grating Welding

Manual welding

Stainless Steel Grating Precautions

Hole spacing center to center

Hole spacing edge to edge

Stainless Steel Grating Projects