Home >> Product >> Compound Steel Grating

Compound Steel Grating

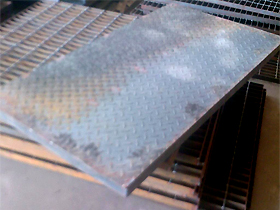

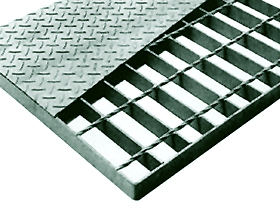

Compound steel grating consists of steel grating plate with certain loading ability and surface seal retreader. After hot dip galvanized treatment, the compound steel grating plate will warp and distort.

Composite steel grating structure is made of steel grid plate keel, tread plate for the surface, welded into a whole. In this way, the use of a non-slip tread plate and non-empty properties, but also make full use of the steel grating better carrying capacity, compared with the simple use of steel tread plate for support, a significant reduction in the use of materials, cost savings.

Compound Steel Grating Application

In the steel grating on the front or bottom of bonding steel plates made of complex networks, can prevent small pieces fall in the granary, restaurants, warehouses complex network board prevents mice and other small animals. Composite steel grating is widely used in power plants, chemical plants, oil refineries, steel mills, paper mills, machinery plants, cement plants, municipal engineering, sewage treatment plants, municipal engineering, environmental engineering and other platforms in certain areas, walkways, trestle , ditch cover, covers, ladders and so on.

Compound Steel Grating Specification

| Specification |

Thickness (mm) |

Tread plate Thickness (mm) |

Steel Grating Specifications |

Maximum span (mm) |

| CTP23 |

23 |

3 |

DG205/40/100 |

1100 |

| CTP28 |

28 |

3 |

DG255/40/100 |

1300 |

| CTP35 |

35 |

3 |

DG325/40/100 |

1600 |

| CTP41 |

41 |

3 |

DG385/40/100 |

1900 |

| CTP47 |

47 |

3 |

DG445/40/100 |

2100 |

| CTP53 |

53 |

3 |

DG505/40/100 |

2400 |

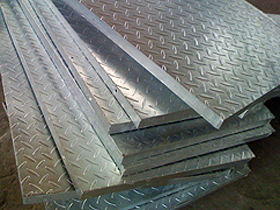

Compound steel grating is formed of any type of steel grating and checkered plate in different thicknesses. The type 323/40/100, 253/30/100 and 323/60/100 are generally used as base & the checkered plate with 3mm thickness is used as sealing plate. Sometimes checkered plate with thickness of 4mm, 5mm or 6mm is also used as sealing plate according to customers' requirements.

Compound Steel Grating Surface Treatment

Untreated

Painting

Hot Dip Galvanizing

Compound Steel Grating Welding

Manual welding

Compound Steel Grating Precautions

1) or directly to the steel grating treads welded to the supporting steel structure, welding zinc-rich paint brush twice.

2) the use of steel grating Milo special mounting clip installation, does not destroy the zinc coating, easy disassembly. Each set includes an upper mounting clip folder, the next clip, M8 head bolts and nuts, one each.

3) according to needs, provide stainless steel mounting clamp or bolt fastening method connectivity.

4) steel grating installation ask gap is generally 100mm.

5) be sure to pay attention when installing solid and reliable installation, you should always check to prevent the mounting clip fall off, close to the best steel grating vibration welding or with rubber pads.

Compound Steel Grating Projects